DPF CLEANING MACHINES V4 Mini and Max

Ideal to regenerate a wide range of particulate filters assembled in the exhausts of various types of vehicles: cars, commercial vehicles, HGV, buses, agricultural and industrial machines, ect. Our product regenerates particulate filters such as: DPP, FAP, GPF as well as SCR- Adblue and so on.

V4 Mini sets

V4 Mini set 1

One – side cleaning

One pump supplying washing and filtration

Two-stage filtration system (two filters)

Black and white display

Drying – 4kW heater

Two ranges of fluid flow regulation

Measurement before and after – final printout

Impact air reservoir (3l)

No expansion of the device possible

V4 Mini set 2

Double-side cleaning (automatic control)

Two pumps supplying washing and filtration.

Three-stage filtration system (three filters)

Color display

Drying – 4kW heater

Two ranges of fluid flow regulation

Measurement before and after – final printout

Impact air reservoir (3l)

The device can be expanded

V4 Mini set 3

Double-side cleaning (automatic control)

Two pumps supplying washing and filtration.

Three-stage filtration system (three filters)

Color display

Drying – 6kW heater (temperature can be set)

Smooth regulation of liquid flow in the system, even up to 270 l/m (useful for cleaning the catalyst)

Measurement before and after – final printout (possibility to test without washing)

Impact air reservoir (3l)

No expansion of the device possible

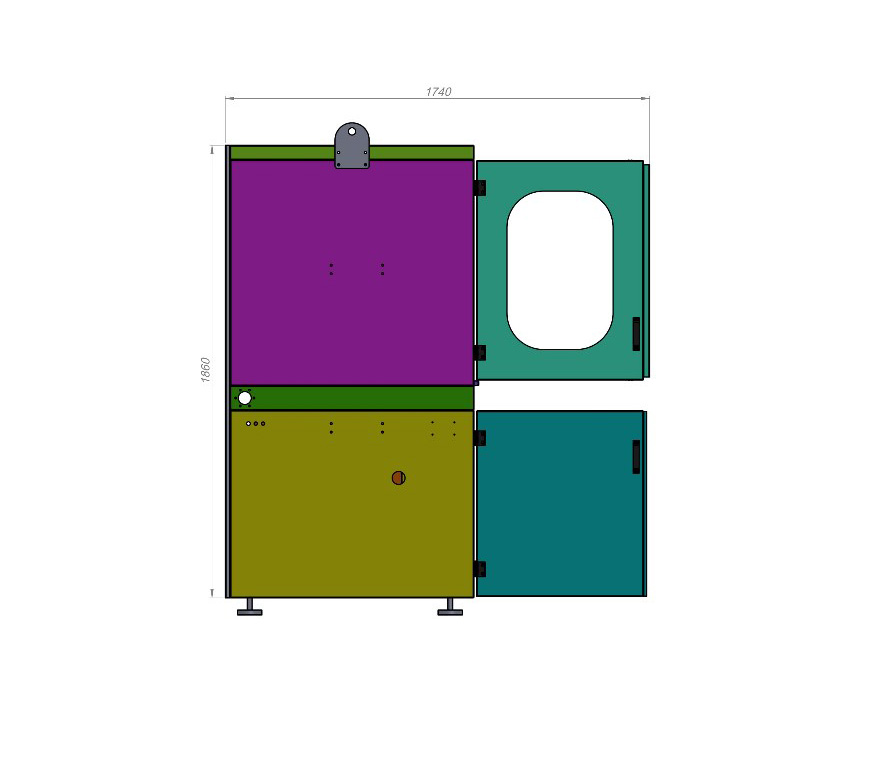

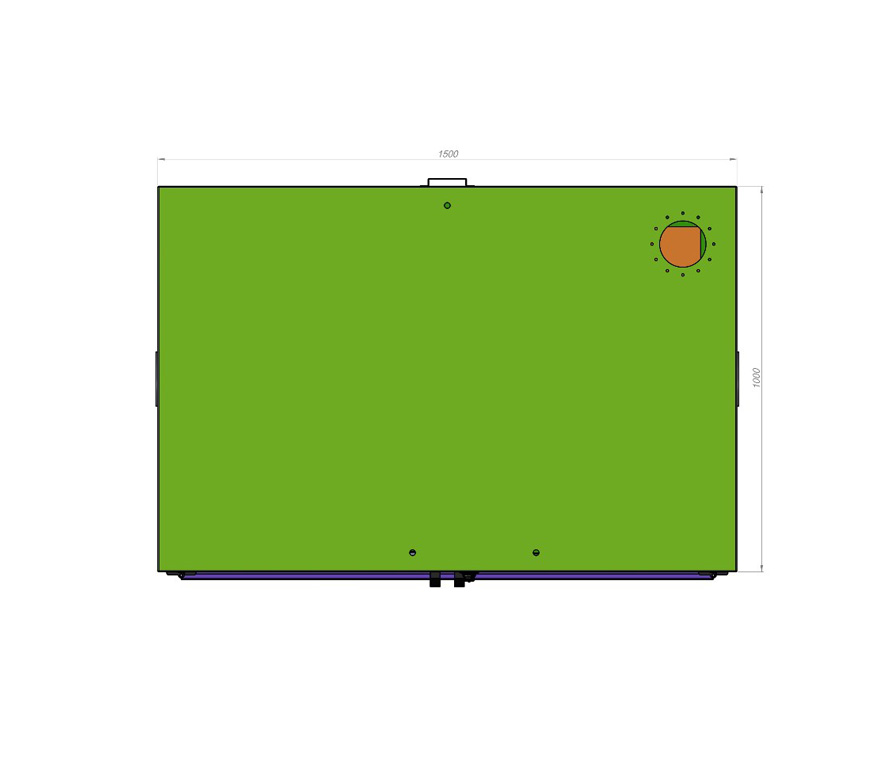

Technical specification V4 Mini

DPF / FAP / GPF / SCR / CAT cleaning machine, particle filter cleaner

| Overall dimensions | width 1500mm x depth 1000mm x height 1860mm |

| Cleaning cabin capacity |

1980mm x 1000mm x 980mm |

| Top load capacity |

220 kg |

| Tank capacity |

330 litrów |

| Weight |

610 kg |

| Power conditions |

Voltage 3x400V, 50Hz compressed air 4-6bar / 120 liters network water |

| Rated power | 12 kW |

|

Water heating |

electrical (max. 80 ° C) |

| Materials | stainless steel AISI 304/316 |

| Type of device operation | Manual, semi-automatic |

| Cleaning agent | Alkaline and natural water solutions |

| Controlling | 24V voltage / B&R controller |

| Cycle time | Adjustable, depending on the type of washing program |

| Function of the machine | Fully automatic, dual regeneration to both sides, (inlet outlet) in a closed circulation |

| Machine equipment | Two closed circuits for washing and filtration of liquids, the first liquid circuit for liquid filtration, the second filtration circuit is located on the pipeline to which the DPF filter is mounted – necessary when washing the Euro 6 filters due to the high porosity of the DPF filter. Variable regulation of water heating by using double heating system, drying function by variable heat airflow, testing system for the flowrate and back pressure, set of the adapters required for fast and easy filter assemby, colorued touch screen control, build-in printer to print the efficiency report, water tank with double bulkheads, safety system, selfdiagnostic/faults detection system |

| Additional equipment | Water recirculation system with an independent pump working in the cycle, that filters cleaning ingredient. |

V4 Max sets

V4 Max set 1

Double-side cleaning (automatic control)

Two pumps supplying washing and filtration

Three-stage filtration system (three filters)

Color display

Drying – 4kW heater

Two ranges of fluid flow regulation

Measurement before and after – final printout

Impact air reservoirs (2l and 5l)

The device can be expanded

V4 Max set 2

Double-side cleaning (automatic control)

Two pumps supplying washing and filtration

Five-stage filtration system (five filters)

Color display

Drying – 6kW heater (temperature can be set)

Smooth regulation of liquid flow in the system, even up to 270 l/m (useful for cleaning the catalyst)

Measurement before and after – final printout (possibility to test without washing)

Impact air reservoirs (2l and 5l)

Information on the level of soiling of the device filters

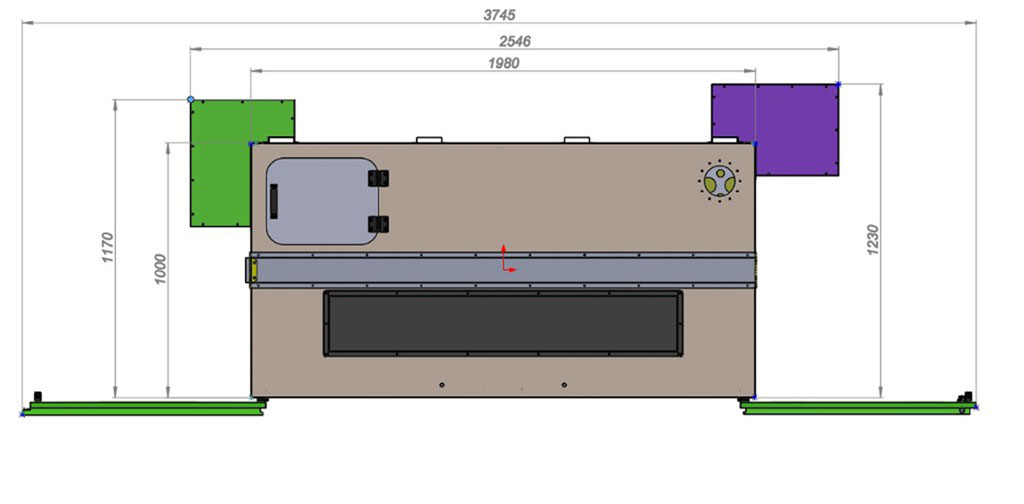

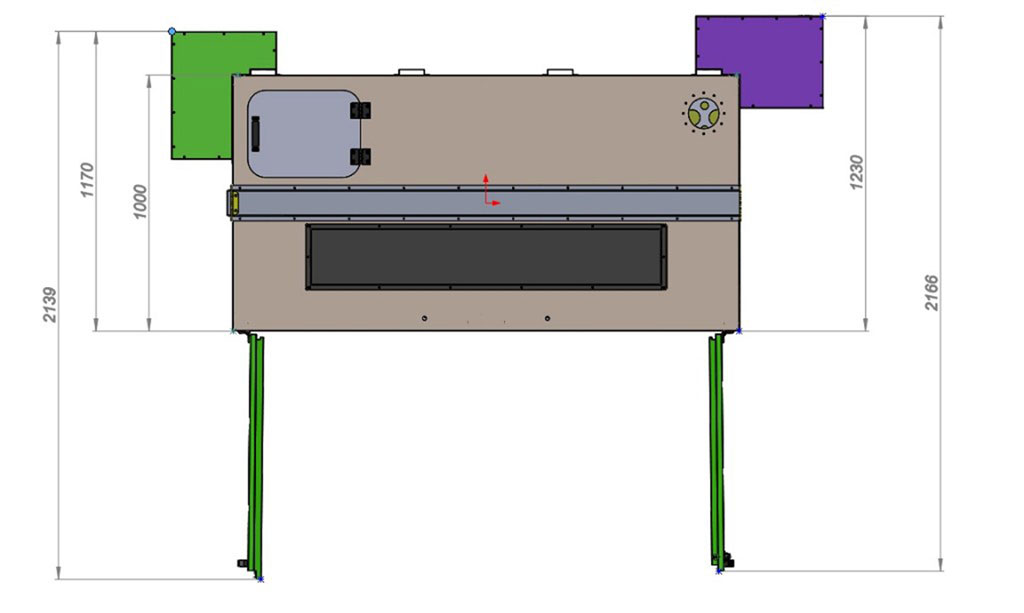

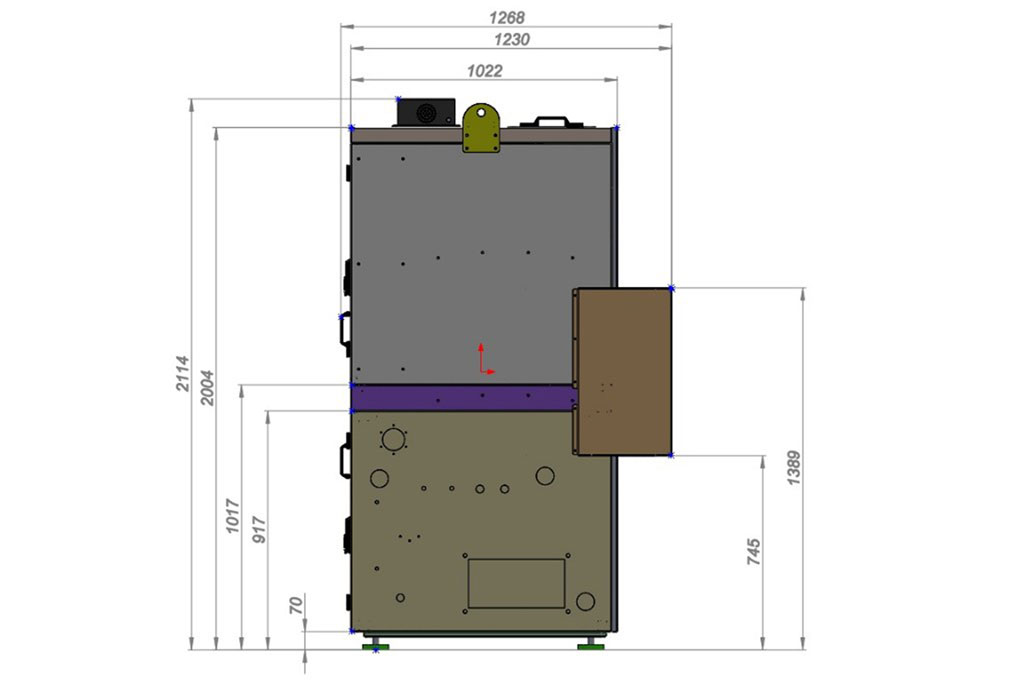

Technical specification V4 Max

DPF / FAP / GPF / SCR / CAT cleaning machine, particle filter cleaner

| Overall dimensions | width 2546mm x depth 1170mm x height 2300mm |

| Cleaning cabin capacity |

1980mm x 1000mm x 980mm |

| Top load capacity |

220 kg |

| Tank capacity |

330 litrów |

| Weight |

810 kg |

| Power conditions |

Voltage 3x400V, 50Hz compressed air 4-6bar / 120 liters network water |

| Rated power | 15 kW |

|

Water heating |

electrical (max. 80 ° C) |

| Materials | stainless steel AISI 304/316 |

| Type of device operation | Semi-automatic |

| Cleaning agent | Alkaline and natural water solutions |

| Controlling | 24V voltage / B&R controller |

| Cycle time | Adjustable, depending on the type of washing program |

| Function of the machine | Fully automatic, dual regeneration to both sides, (inlet outlet) in a closed circulation |

| Machine equipment | Two closed circuits for washing and filtration of liquids, the first liquid circuit for liquid filtration, the second filtration circuit is located on the pipeline to which the DPF filter is mounted – necessary when washing the Euro 6 filters due to the high porosity of the DPF filter. Variable regulation of water heating by using double heating system, drying function by variable heat airflow, testing system for the flowrate and back pressure, set of the adapters required for fast and easy filter assemby, colorued touch screen control, build-in printer to print the efficiency report, water tank with double bulkheads, safety system, selfdiagnostic/faults detection system |

| Additional equipment | Water recirculation system with an independent pump working in the cycle, that filters cleaning ingredient. |

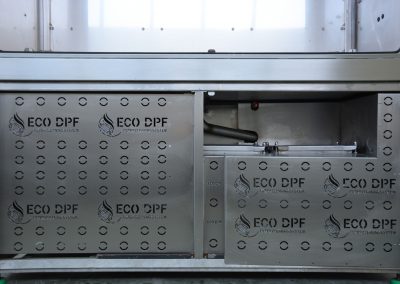

The main features of the machine

The cleaning flow in the V4 machine is cyclically supplied , to both sides of the filter ( inlet outlet)

No need to swap the filter connection sides (inlet, outlet) in the machine, during the cleaning.

It is an innovative solution on the market nowadays.

Our machine is equipped with the wide range of adapters, universal connectors and units making filter fitting in the machine safe and easy. Also the number of sets of particular adapters can be increased or modified to meet the customers’ needs.

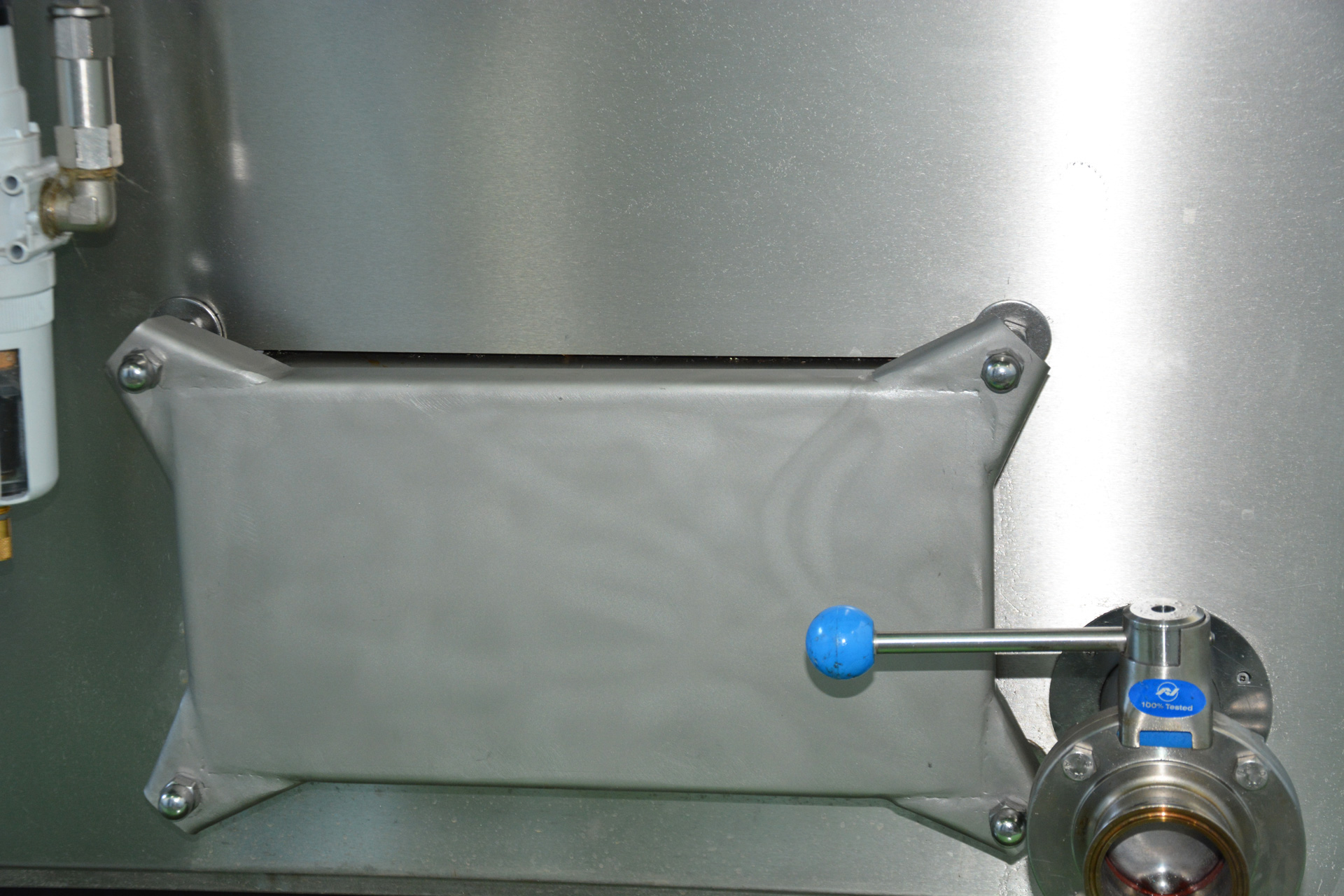

Innovative construction of the water tank enables to easily clean it. Access through 3 revision hatches, with no need of taking the tank out of the machine. We can safely use the pressure washer if needed.

Machine features

An innovative mechanism with an universal construction based on integration of many solutions. Making regeneration/cleaning of any particular filters – a short and easy action,

In our machine V4 the cleaning flow is composed of a unique mixture of air, water and chemical cleaning solution. This enables to remove all the traces of particulates from the filter (ache, soot, oli-remains)

The efficiency of the V2/3 machine is verified by the rate flow and backpressure tests run before and after cleaning. The report of the results is printed and shows the efficiency of the filter after regeneration.

Our cleaner works along various programs especially designed to wash different types of filters, such as car, commercial vehicle, HGV, bus, industrial and agricultural fi ect. It means that its functionality can be improved by increasing or decreasing its working time.

V2/3 Machine is made of a high quality materials. The stainless steel AISI304, was used to build the whole frame and case of the device, as well was water tank, filter housings. Also the high volume of subassemblies are made of AISI 316 stainless steel. Moreover the electric distribution board and water tank are fully separated by double stainless steel.

The water used in our product is always clean. Thanks to separate filtration pump working along with double filters. Moreover the level of water is refilled from the pipeline automatically.

Our machine is equipped with the wide range of adapters, universal connectors and units making filter fitting in the machine safe and easy.

Regeneration in the V2/3 machine regain the filter functionality, even though the service regeneration failed.

The cleaning flow is supplied cyclically to both sides of the filter. Inlet and outlet supply. There is no need to change the position of the filter during the cleaning process.

V2/3 machine meets the extremely strict environmental rules by using closed circuit along with simultaneous filtration of the cleaning flow. The circuit is ruled by two independent pumps. All the contamination generated during the regeneration is kept in the hermetic tank, so that it does not go outside the machine itself. The tank can be easily clean.

The drying process is run automatically straight after the cleaning. The V2/3 machine uses electric air heater, so the filter is dried with high temperature to reassure removal of any traces of dump.

Our cleaning device is equipped with a high class PLC Controler. It manages the whole cleaning process. It is controlled through the colourful touch screen alternately via Smartphone, Tablet (Android, iOS)

The V2/3 machine uses integrated safety systems.

So that it protects: major circuit from phase loss or its wrong order and voltage loss, water heaters by controlling the required level of water, door against an accidental opening.

Moreover the Self-diagnostic module detect the machine faults to enable fast easy faults localisation.

The V4 machine comes with a builds in printer, that prints the end report with the filter efficiency before and after cleaning.

MAKE AN APPOINTMENT NOW WITH OUR ONLINE FORM

CONTACT

Adress

Unit 6 Carrington Court Great Northern Road, Derby DE1 1LR